Sabatti's willingness to give its shotguns on trial is truly exemplary and that of Massimo Felicetta, the area agent, in favoring these beautiful experiences in every way is no exception. Here we are in the interesting circuit between the Carrù polygon and the AAFV La Benese di Benevagienna, a town very close to each other and located in the province of Cuneo.

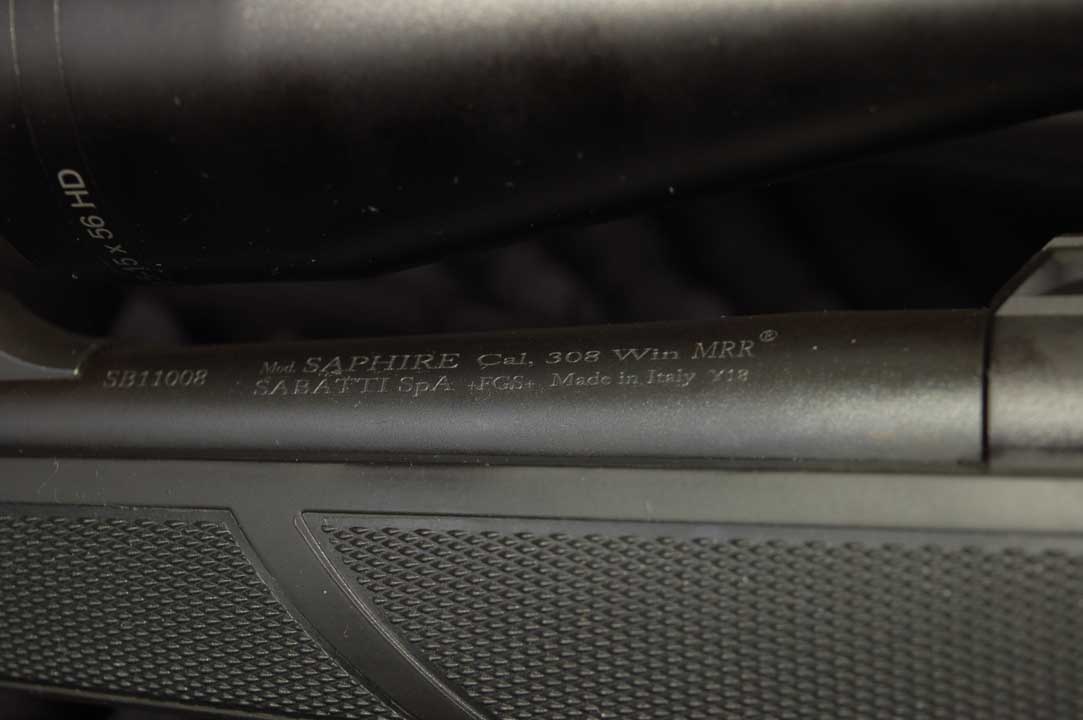

The preventive visit to the shooting range was due to double check the calibration of two Sabatti Saphire in .308 Win. to which the power supply had changed ... yes basically we used different cartridges from those for which they had been developed previously. We took advantage of the circumstance and, after the tests on the counter, we dedicated ourselves to a re-examination of this recent model fielded by the Gardonese company.

The salient features

The peculiarity of the Saphira compared to the well-known Rover is the interchangeable barrel for groups of calibers and the castle, always in a single block machined with a cutter, but obtained from an extruded Ergal 55. The formula adopted with a front ring under which protrudes the force discharge prism and closed rear bridge, joined by side profiles with a rounded section: on the two apical elements the Picatinny-type slide sections are obtained, ready for the assembly of the bases of an optic and guaranteed in their coaxiality with the entire castle and barrel. The ejection window is contained like the slot for loading the magazine: less material is removed, increasing rigidity.

In the back you can still see the recess to house the handlebar and, in the curvature behind the bridge, the insertion of a steel pad where the handlebar profile is in contrast to ensure primary extraction: therefore the hardness differential is avoided. a harbinger of premature wear of the softer material. The rocker lever protrudes on the left side for releasing the shutter at the end of the stroke: a functional system that does not require you to touch the trigger for the purpose to be reached. There are other interesting solutions for the shutter obtained from a large diameter steel cylinder on which the head with three fins obtained within the main section is placed: the floating assembly guarantees a correct adaptation and therefore a perfect adherence of the surfaces resistant to mortises obtained within the breech of the barrel.

This last detail is an additional piece: the interruption of the continuity solution is no longer a problem given the control systems for the union of the specific piece with the barrel: on the contrary, the method allows, thanks also to the processing by casting, to vary the thermochemical treatments, according to the desired specifications with high degrees of surface hardness together with the toughness of the internal mass with maximum resistance combined with the ability to absorb forces without the formation of crystallizations and consequent fractures. Here the material and the treatments are the same for the two pieces that determine the closure, therefore head and breech extension with mortises. To finish the examination of the head we mention the recess where the cartridge bottom is housed and the elastic pawl of the ejector protrudes, next to the egress hole of the firing pin. The nail of the extractor is sturdy and equipped with a prism base orthogonally recessed in the flap at the top left for the observer: a ball pushed by a spring creates the right contrast, preventing the case from overlapping.

The replacement of the barrel goes hand in hand with the replacement of the head: three groups of cartridges where we see the .243 Win. Series, that of the .30-06 Sprg. and finally 7 Rem. Mag. And the .300 Win. Mag. The coupling with an orthogonal drawstring ensures that the load is counteracted at the peak, therefore with the maximum safety guaranteed by the sections in play.

The insertion of the handlebar is entrusted to a joint: one of the two rifles in question has a rather extended arm, bent at the bottom and with a grip point in synthetic conical cylinder, the other a spatula profile with rounded apex. The first perhaps more suitable for shooting, the other for hunting with less lateral overhang and an eye to the Mannlicher style: both very comfortable and functional. The shaped apical cap completes the obturator: the protruding tang acts as a warning of armed mechanics.

Barrel and stock

The barrels of the two shotguns are 61 cm long and have a muzzle brake with radial holes with minimal differences in the profile: on the other hand they are identical in the rifling of the Sabatti - MRR® multiradial type with elimination of the edges between full and empty replaced by a continuous curvature with two spokes: the step is 1:11 ”. Compared to a traditional rifling, the solution guarantees, all factors being equal, greater ball speed with less deformation, increased accuracy, reduction of parasitic deposits, ease of cleaning. Another detail is the separate processing of the cartridge chamber from which greater perfection and then optimal centering are obtained thanks to the machinery available today. One specimen does not have metal sights, present in the other with a U-shaped notch and adjustable blade front sight, with matte black sight, mounted on a ramped base.

The stocks are similar in terms of the synthetic material used and the pistol grip with a large slit for the passing hand: it is a very advantageous solution for targeted shooting, but with a little training, it becomes functional and quick to grip even in arm shooting. loose on moving targets. The model more aimed at shooting also has an adjustable cheek rest and a Picatinny-type sled under the shaft.

Conclusions

It is a pity that the wild boar did not show up, but the tests conducted in the shooting range for the calibrations were once again of full satisfaction: this Saphire is fully occupying a prominent place in the panorama of long rifled guns available on our market.